Researchers have developed a low-cost, energy-efficient method for making materials that can capture carbon dioxide directly from the air.

An international team including Phillip Milner, assistant professor of chemistry in the College of Arts & Sciences, used a method similar to charging a battery to instead charge activated charcoal, which is often used in household water filters.

By charging the charcoal ‘sponge’ with ions that form reversible bonds with CO2, the researchers found the charged material could successfully capture CO2 directly from the air.

The charged charcoal sponge is also potentially more energy efficient than current carbon capture approaches, since it requires much lower temperatures to remove the captured CO2 so it can be stored. The results are reported in “Capturing carbon dioxide from air with charged-sorbents,” published June 5 in the journal Nature.

“Capturing carbon emissions from the atmosphere is a last resort, but given the scale of the climate emergency, it’s something we need to investigate,” said Alexander Forse from the University of Cambridge, who led the research. “The first and most urgent thing we’ve got to do is reduce carbon emissions worldwide, but greenhouse gas removal is also thought to be necessary to achieve net zero emissions and limit the worst effects of climate change. Realistically, we’ve got to do everything we can.”

Direct air capture, which uses sponge-like materials to remove carbon dioxide from the atmosphere, is one potential approach for carbon capture, but current approaches are expensive, require high temperatures and the use of natural gas, and lack stability.

The Cornell team, led by doctoral candidates Mary Zick Ph.D. ’23 and S. Alexandra Lim, helped to study the carbon capture kinetics of these materials under direct air capture conditions, demonstrating that they show rapid uptake that is comparable to state-of-the-art materials. They also demonstrated the ability of the material to resist chemical changes over long periods of storage (oxidative stability) under harsh conditions.

“The primary challenge with these novel materials has been figuring out how to get the negatively charged hydroxide ions into the sponges,” said Milner. “We were excited to work with the Forse group to prove these materials have extremely good stability under harshly oxidizing conditions, an important consideration for their industrial application.”

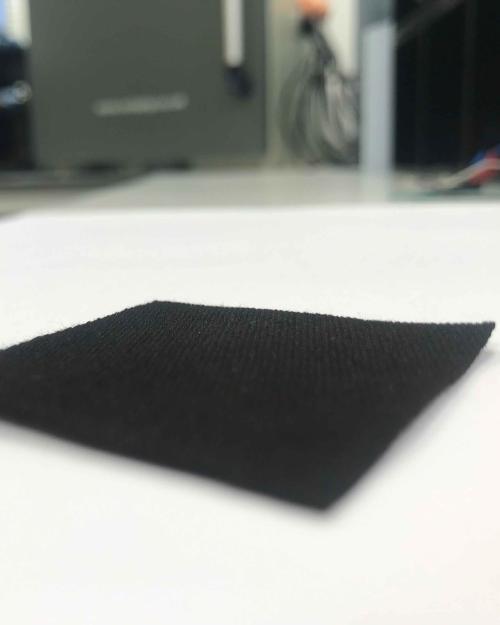

Activated charcoal is used in many purification applications, such as water filters, but normally it can’t capture and hold CO2 from the air. The researchers proposed that if activated charcoal could be charged, like a battery, it could be a suitable material for carbon capture.

When charging a battery, charged ions are inserted into one of the battery’s electrodes. The researchers hypothesised that charging activated charcoal with chemical compounds called hydroxides would make it suitable for carbon capture, since hydroxides form reversible bonds with CO2.

The team used a battery-like charging process to charge an inexpensive activated charcoal cloth with hydroxide ions. In this process, the cloth essentially acts like an electrode in a battery, and hydroxide ions accumulate in the tiny pores of the charcoal. At the end of the charging process, the charcoal is removed from the “battery,” washed and dried.

Tests of the charged charcoal sponge showed that it could successfully capture CO2 directly from the air, thanks to the bonding mechanism of the hydroxides.

To collect the CO2 from the charcoal so it can be purified and stored, the material is heated to reverse the hydroxide-CO2 bonds. In most materials currently used for CO2 capture from air, the materials need to be heated to temperatures as high as 900°C, often using natural gas. However, the charged charcoal sponges developed by the Cambridge team only require heating to 90-100°C, temperatures that can be achieved using renewable electricity. The materials are heated through resistive heating, which essentially heats them from the inside out, making the process faster and less energy-intensive.

The materials do, however, have limitations that the researchers are now working on, to increase how much carbon dioxide can be captured, especially under humid conditions where capture is less efficient.

The researchers say their approach could be useful in fields beyond carbon capture, since the pores in the charcoal and the ions inserted into them can be fine-tuned to capture a range of molecules.

“This approach opens a door to making all kinds of materials for different applications, in a way that’s simple and energy-efficient,” said Forse.