On-demand polymers may yield designer materials

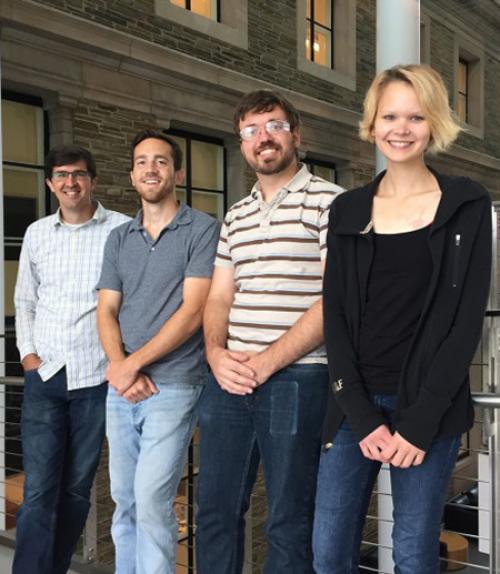

Researchers at Cornell are devising a method for creating new polymers in much the same way that a jewelry maker creates a beaded necklace.

More news

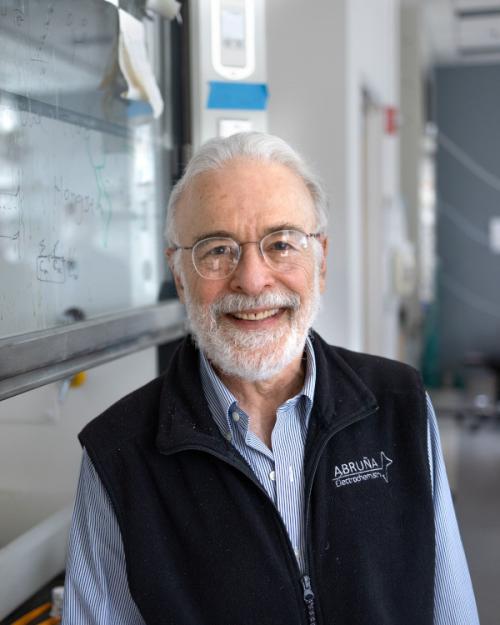

Abruña honored for chemistry in the public interest

A&S Communications

Student spotlight: Bayu Ahmad

Cornell University Graduate School